penerangan

sistem pengekodan tygk

|

kategori pengeluaran ① |

②tygk gred |

③type classfication |

④shape code |

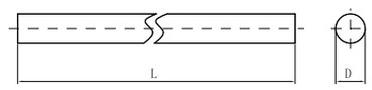

⑤diameter |

⑥lengh |

|

h0-tanah |

25u-ty25uf |

br-rods |

1-no chamfer |

|

|

|

h1-setengah-tanah |

25s-ty25s |

bq-ball-nose endmill kosong |

2-chamfer |

|

|

|

h2-ground h6 |

20-ty20 |

bt step-rods |

3-double chamfer |

|

|

|

h7-ground h7 |

05a-ty05a |

|

|

|

|

|

|

10u-ty10uf |

|

|

|

|

pengenalan gred

|

gred |

gred aplikasi iso |

grasiz (μm) |

kandungan kobal (%) |

hardnes (hra) |

ketumpatan (g/cm³)

|

trs (n/m²) |

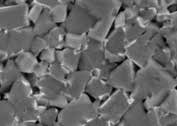

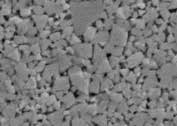

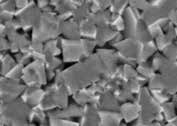

mikrostruktur 10000x |

|

ty05a |

k15 |

1.0 |

6.0 |

92.5 |

14.95 |

2450 |

|

|

ty10uf |

k05-k10 |

0.4 |

6.0 |

94.0 |

14.80 |

3800 |

|

|

ty20 |

k20-k40 |

0.6 |

10.0 |

91.8 |

14.45 |

3800 |

|

|

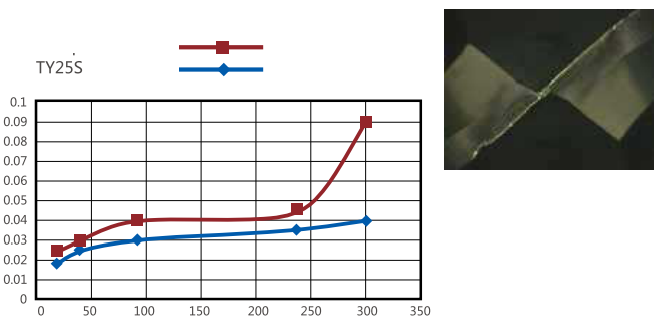

ty25s |

k20-k40 |

0.5 |

11.0 |

92.4 |

14.25 |

4000 |

|

|

ty25uf |

k20-k40 |

0.4 |

12.0 |

92.5 |

14.10 |

4200 |

|

|

|

ty10uf |

ty25s |

ty25uf |

ty20 |

ty05a |

|

|

jenis alat pemotongan |

gred yang disyorkan (sesuai: △) |

|||||

|

endmill |

|

△ |

△ |

△ |

△ |

|

|

latihan |

△ |

△ |

△ |

△ |

△ |

|

|

reamer |

|

△ |

△ |

△ |

|

|

|

bahan kerja |

gred yang disyorkan (◎: terbaik; ο: sesuai) |

|||||

|

|

keluli bukan aloi |

Ο |

◎ |

◎ |

◎ |

|

|

p |

keluli aloi rendah |

|

Ο |

Ο |

|

◎ |

|

|

keluli aloi yang tinggi |

|

◎ |

◎ |

◎ |

|

|

m |

keluli tahan karat |

Ο |

|

◎ |

|

|

|

|

besi tuang kelabu |

Ο |

◎ |

Ο |

◎ |

◎ |

|

k |

besi tuang besi |

|

|

Ο |

◎ |

|

|

|

besi grafit spheroidal |

◎ |

◎ |

Ο |

Ο |

Ο |

|

n |

aloi aluminium |

|

Ο |

Ο |

◎ |

Ο |

|

copperalloy |

|

◎ |

◎ |

◎ |

Ο |

|

|

s |

aloi nikel |

|

|

◎ |

◎ |

◎ |

|

aloi titanium |

|

◎ |

◎ |

◎ |

◎ |

|

|

h |

keluli keras |

|

|

◎ |

Ο |

◎ |

|

yang lain |

kayu |

|

Ο |

Ο |

Ο |

Ο |

|

plastik bertetulang kaca serat |

|

◎ |

◎ |

|

◎ |

|

|

komposit |

|

◎ |

◎ |

Ο |

Ο |

|

ty25s: endmil 、 reamers dan gravers disyorkan. prestasi yang lebih tinggi untuk pemotongan berkelajuan tinggi. sesuai untuk memotong keluli keras, aloi aluminium dan aloi titanium.

ty20: drill dan endminlls disyorkan. boleh dimuatkan untuk pemotongan keluli mati 、 kelabu besi tuang 、 austenitic stainles steel dan aloi tahan haba.

ty05a: drill 、 endmil dan burr disyorkan. sesuai untuk pemotongan logam, aluminium, tembaga dan grafit yang tidak ferous (salutan yang diperlukan)

cadangan gred ini adalah untuk rujukan anda sahaja, kerana bentuk alat pemotongan dan salutan kedua -duanya mempunyai pengaruh yang besar terhadap prestasi alat pemotongan. sila pergi ke gred khusus untuk maklumat lanjut untuk membantu pilihan gred anda.

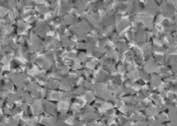

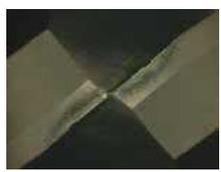

kes ty20

pengilangan die steel (40hrc)

|

|

bahan kerja |

jenis alat |

gred |

||

|

bekerja keadaan |

mati keluli skd61 (40hrc) |

endmill |

ty20 |

||

|

mill dia. (mm) |

panjang seruling (mm) |

bilangan seruling (n) |

salutan |

penyejukan |

|

|

8 |

20 |

4 |

alcrn |

larut air |

|

keadaan pemotongan:

vc = 95m/min

fz = 840mm/min ae = 0.8mm

ap = 8mm

hidup +60%

panjang pemotongan (m)

pesaing o syarikat

pesaing o syarikat ty20

ty20

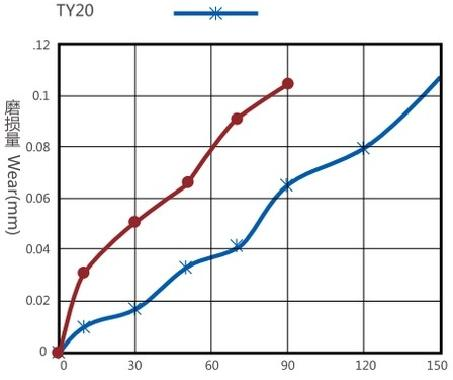

kes ty25s

pengilangan die steel (55hrc)

|

|

bahan kerja |

jenis alat |

gred |

||

|

bekerja keadaan |

die steel skd61 (55hrc) |

endmill |

ty25s |

||

|

mill dia. (mm) |

panjang seruling (mm) |

bilangan seruling (n) |

salutan |

penyejukan |

|

|

6 |

- |

2 |

tiain |

minyak kabut |

|

keadaan pemotongan:

vc = 254m/min

fz = 4200mm/min ae = 0.2mm

ap = 2mm

hidup +60%

panjang pemotongan (m) syarikat pesaing m

ty25s

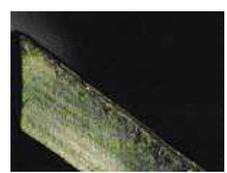

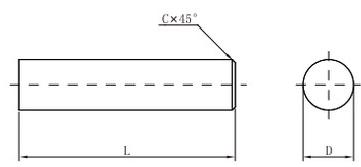

batang tanah dengan chamfer

batang tanah dengan chamfer -inch

|

kategori tygkproduction h2/h7 iso h6/h5 |

||||

|

spesifikasi |

dimensi |

tol.of od |

||

|

od |

l. |

h6 |

h5 |

|

|

br2031038 |

1/8 |

1/2 |

√ |

√ |

|

br2031050 |

1/8 |

2 |

√ |

√ |

|

br2031063 |

1/8 |

2-1/2 |

√ |

√ |

|

br2031076 |

1/8 |

3 |

√ |

√ |

|

br2047050 |

3/16 |

2 |

√ |

√ |

|

br2047076 |

3/16 |

3 |

√ |

√ |

|

br2063050 |

1/4 |

2 |

√ |

√ |

|

br2063063 |

1/4 |

2-1/2 |

√ |

√ |

|

br2063076 |

1/4 |

3 |

√ |

√ |

|

br2063101 |

1/4 |

4 |

√ |

√ |

|

br2079063 |

5/16 |

2-1/2 |

√ |

√ |

|

br2050100 |

5.0 |

100 |

√ |

√ |

|

br2050150 |

5.0 |

150 |

√ |

√ |

|

br2060050 |

6.0 |

50 |

√ |

√ |

|

br2060060 |

6.0 |

60 |

√ |

√ |

|

br2060075 |

6.0 |

75 |

√ |

√ |

|

br2060100 |

6.0 |

100 |

√ |

√ |

|

br2060150 |

6.0 |

150 |

√ |

√ |

|

br2070055 |

7.0 |

55 |

√ |

√ |

|

br2070060 |

7.0 |

60 |

√ |

√ |

|

br2080060 |

8.0 |

60 |

√ |

√ |

|

br2080075 |

8.0 |

75 |

√ |

√ |

|

br2080080 |

8.0 |

80 |

√ |

√ |

|

br2080090 |

8.0 |

90 |

√ |

√ |

|

br2080100 |

8.0 |

100 |

√ |

√ |

|

br2080150 |

8.0 |

150 |

√ |

√ |

|

br2100070 |

10.0 |

70 |

√ |

√ |

|

br2100075 |

10.0 |

75 |

√ |

√ |

|

br2100090 |

10.0 |

90 |

√ |

√ |

|

br2100100 |

10.0 |

100 |

√ |

√ |

|

br2100125 |

10.0 |

125 |

√ |

√ |

|

br2120110 |

11.0 |

110 |

√ |

√ |

|

br2120075 |

12.0 |

75 |

√ |

√ |

|

br2120090 |

12.0 |

90 |

√ |

√ |

|

br2120100 |

12.0 |

100 |

√ |

√ |

|

br2120120 |

12.0 |

120 |

√ |

√ |

|

br2140075 |

14.0 |

75 |

√ |

√ |

|

br2140110 |

14.0 |

110 |

√ |

√ |

|

br2140125 |

14.0 |

125 |

√ |

√ |

|

br2160100 |

16.0 |

100 |

√ |

√ |

|

br2160125 |

16.0 |

125 |

√ |

√ |

|

br2180100 |

18.0 |

100 |

√ |

√ |

|

br2180150 |

18.0 |

150 |

√ |

√ |

|

br2200100 |

20.0 |

100 |

√ |

√ |

|

br2200120 |

20.0 |

120 |

√ |

√ |

|

br2200150 |

20.0 |

150 |

√ |

√ |

|

br2250100 |

25.0 |

100 |

√ |

√ |

|

br2250150 |

25.0 |

150 |

√ |

√ |

|

|

|

|

|

|

|

|

diameter d, inci |

chamfer c, inci |

||

|

(julat) |

(tol.) |

(julat) |

(tol.) |

|

|

1/8≤0ds1 |

h5, h6 |

1/8s0d <7/16 |

+.015±.004 |

|

|

|

|

7/16sods1 |

+.031±.008 |

|

|

panjang l, inci |

sudut, darjah |

|||

|

(julat) |

(tol.) |

(julat) |

(tol.) |

|

|

1/2≤ls3/4 |

+1/16,-0 |

1/8sod≤1 |

45°±3° |

|

(1) br2 thecode untuk siri dengan chamfer adalah br2

(2) br1 kod yang tidak dapat dipertahankan tanpa chamfer adalah br1

(3) br3 kod untuk siri withtwo chamfers adalah br3

unit (inci)

contoh pesanan:

(jenisnya adalah untuk pesanan contoh, yang bawahnya oren.)

|

jadual pesanan |

||||||

|

tidak. |

gred |

jenis pesanan |

kategori & jenis pengeluaran |

tol. |

jumlah |

catatan |

|

1 |

ty20 |

h2-br2031038 |

tygk |

5000 |

|

|

|

2 |

|

|

|

|

|

|

nota: ia akan diambil sebagai standard tygk, jika tiada toleransi yang diserahkan.

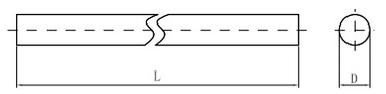

batang ungung

rod ungung -unch

|

kategori pengeluaran tygk ho: kekosan |

||

|

spesifikasi |

dimensi |

|

|

od |

l. |

|

|

br1031333 |

1/8 |

13-1/8 |

|

br1035333 |

9/64 |

13-1/8 |

|

br1039333 |

5/32 |

13-1/8 |

|

br1043333 |

11/64 |

13-1/8 |

|

br1047333 |

3/16 |

13-1/8 |

|

br1051333 |

13/64 |

13-1/8 |

|

br1055333 |

7/32 |

13-1/8 |

|

br1059333 |

15/64 |

13-1/8 |

|

br1063333 |

1/4 |

13-1/8 |

|

br1071307 |

9/32 |

12-1/8 |

|

br1075307 |

19/64 |

12-1/8 |

|

br1079307 |

5/16 |

12-1/8 |

|

br1083307 |

21/64 |

12-1/8 |

|

br1087307 |

11/32 |

12-1/8 |

|

br1091307 |

23/64 |

12-1/8 |

|

br1095307 |

3/8 |

12-1/8 |

|

br1099307 |

25/64 |

12-1/8 |

|

br1103307 |

13/32 |

12-1/8 |

|

br1107307 |

27/64 |

12-1/8 |

|

br1111307 |

7/16 |

12-1/8 |

|

br1115307 |

29/64 |

12-1/8 |

|

br1119307 |

15/32 |

12-1/8 |

|

br1123307 |

31/64 |

12-1/8 |

|

br1127307 |

1/2 |

12-1/8 |

|

br1134307 |

17/32 |

12-1/8 |

|

br1142307 |

9/16 |

12-1/8 |

|

br1158307 |

5/8 |

12-1/8 |

|

br1174307 |

11/16 |

12-1/8 |

|

br1190307 |

3/4 |

12-1/8 |

|

br1206307 |

13/16 |

12-1/8 |

|

br1222307 |

7/8 |

12-1/8 |

|

br1238307 |

15/16 |

12-1/8 |

|

br1254307 |

1 |

12-1/8 |

|

br1020330 |

2.0 |

330 |

|

br1025330 |

2.5 |

330 |

|

br1030330 |

3.0 |

330 |

|

br1035330 |

3.5 |

330 |

|

br1040330 |

4.0 |

330 |

|

br1045330 |

4.5 |

330 |

|

br1050330 |

5.0 |

330 |

|

br1060330 |

6.0 |

330 |

|

br1065330 |

6.5 |

330 |

|

br1070330 |

7.0 |

330 |

|

br1075330 |

7.5 |

330 |

|

br1080330 |

8.0 |

330 |

|

br1085330 |

8.5 |

330 |

|

br1090330 |

9.0 |

330 |

|

br1095330 |

9.5 |

330 |

|

br1100330 |

10.0 |

330 |

|

br1105330 |

10.5 |

330 |

|

br1110330 |

11.0 |

330 |

|

br1115330 |

11.5 |

330 |

|

br1120330 |

12.0 |

330 |

|

br1125330 |

12.5 |

330 |

|

br1130330 |

13.0 |

330 |

|

br1135330 |

13.5 |

330 |

|

br1140330 |

14.0 |

330 |

|

br1145330 |

14.5 |

330 |

|

br1150330 |

15.0 |

330 |

|

br1155330 |

15.5 |

330 |

|

br1160330 |

16.0 |

330 |

|

br1165330 |

16.5 |

330 |

|

br1170330 |

17.0 |

330 |

|

br1175330 |

17.5 |

330 |

|

br1180330 |

18.0 |

330 |

|

br1185330 |

18.5 |

330 |

|

br1190330 |

19.0 |

330 |

|

br1195330 |

19.5 |

330 |

|

br1200330 |

20.0 |

330 |

|

br1205330 |

20.5 |

330 |

|

br1210330 |

21.0 |

330 |

|

br1215330 |

21.5 |

330 |

|

br1220330 |

22.0 |

330 |

|

br1225330 |

22.5 |

330 |

|

br1230330 |

23.0 |

330 |

|

br1235330 |

23.5 |

330 |

|

br1240330 |

24.0 |

330 |

|

br1245330 |

24.5 |

330 |

|

br1250330 |

25.0 |

330 |

|

br1255330 |

25.5 |

330 |

|

br1260330 |

26.0 |

330 |

|

br1265330 |

26.5 |

330 |

|

br1270330 |

27.0 |

330 |

|

br1275330 |

27.5 |

330 |

|

br1280330 |

28.0 |

330 |

|

br1285330 |

28.5 |

330 |

|

br1290330 |

29.0 |

330 |

|

br1300330 |

30.0 |

330 |

|

br1305330 |

30.5 |

330 |

|

br1310330 |

31.0 |

330 |

|

br1315330 |

31.5 |

330 |

|

br1320330 |

32.0 |

330 |

|

br1325330 |

32.5 |

330 |

|

br1330330 |

33.0 |

330 |

|

br1335330 |

33.5 |

330 |

|

br1340330 |

34.0 |

330 |

|

br1345330 |

34.5 |

330 |

|

br1350330 |

35.0 |

330 |

|

br1355330 |

35.5 |

330 |

|

br1360330 |

36.0 |

330 |

|

br1365330 |

36.5 |

330 |

|

br1370330 |

37.0 |

330 |

|

br1375330 |

37.5 |

330 |

|

br1380330 |

38.0 |

330 |

|

br1385330 |

38.5 |

330 |

|

br1390330 |

39.0 |

330 |

|

br1400330 |

40.0 |

330 |

|

br1405330 |

40.5 |

330 |

|

br1410330 |

41.0 |

330 |

|

br1415330 |

41.5 |

330 |

|

br1420330 |

42.0 |

330 |

|

standard |

diameter d, mm |

|

|

julat |

tol. |

|

|

2≤0d <3 |

+0.15~+0.30 |

|

|

3≤od≤6 |

+0.30~+0.50 |

|

|

6 |

+0.30~+0.60 |

|

|

12 |

+0.30~+0.70 |

|

|

16 |

+0.30~+0.80 |

|

|

panjang l, mm |

||

|

julat |

tol. |

|

|

330 |

+5,-0 |

|

batang tanah

inci

|

iso h6/h5 kategori pengeluaran tygk h2/h7 |

||

|

spesifikasi |

dimensi |

|

|

od |

l. |

|

|

br1063307 |

1/4 |

12-1/2 |

|

br1071307 |

9/32 |

12-1/2 |

|

br1075307 |

19/64 |

12-1/2 |

|

br1079307 |

5/16 |

12-1/2 |

|

br1083307 |

21/64 |

12-1/2 |

|

br1087307 |

11/32 |

12-1/2 |

|

br1091307 |

23/64 |

12-1/2 |

|

br1095307 |

3/8 |

12-1/2 |

|

br1099307 |

25/64 |

12-1/2 |

|

br1103307 |

13/32 |

12-1/2 |

|

br1107307 |

27/64 |

12-1/2 |

|

br1111307 |

7/16 |

12-1/2 |

|

br1115307 |

29/64 |

12-1/2 |

|

br1119307 |

15/32 |

12-1/2 |

|

br1123307 |

31/64 |

12-1/2 |

|

br1127307 |

1/2 |

12-1/2 |

|

br1134307 |

17/32 |

12-1/2 |

|

br1142307 |

9/16 |

12-1/2 |

|

br1158307 |

5/8 |

12-1/2 |

|

br1174307 |

11/16 |

12-1/2 |

|

br1190307 |

3/4 |

12-1/2 |

|

br1206307 |

13/16 |

12-1/2 |

|

br1222307 |

7/8 |

12-1/2 |

|

br1238307 |

15/16 |

12-1/2 |

|

br1254307 |

1 |

12-1/2 |

|

br1060330 |

6 |

330 |

|

br1070330 |

7 |

330 |

|

br1080330 |

8 |

330 |

|

br1090330 |

9 |

330 |

|

br1100330 |

10 |

330 |

|

br1110330 |

11 |

330 |

|

br1120330 |

12 |

330 |

|

br1130330 |

13 |

330 |

|

br1140330 |

14 |

330 |

|

br1150330 |

15 |

330 |

|

br1160330 |

16 |

330 |

|

br1170330 |

17 |

330 |

|

br1180330 |

18 |

330 |

|

br1190330 |

19 |

330 |

|

br1200330 |

20 |

330 |

|

br1210330 |

21 |

330 |

|

br1220330 |

22 |

330 |

|

br1230330 |

23 |

330 |

|

br1240330 |

24 |

330 |

|

br1250330 |

25 |

330 |

|

br1260330 |

26 |

330 |

|

br1270330 |

27 |

330 |

|

br1280330 |

28 |

330 |

|

br1290330 |

29 |

330 |

|

br1300330 |

30 |

330 |

|

br1310330 |

31 |

330 |

|

br1320330 |

32 |

330 |

|

br1330330 |

33 |

330 |

|

br1340330 |

34 |

330 |

|

br1350330 |

35 |

330 |

|

br1360330 |

36 |

330 |

|

br1370330 |

37 |

330 |

|

br1380330 |

38 |

330 |

|

br1390330 |

39 |

330 |

|

br1400330 |

40 |

330 |

|

br1410330 |

41 |

330 |

|

br1420330 |

42 |

330 |

|

standard |

diameter d, mm |

|

|

julat |

tol. |

|

|

6 |

h6, h5 |

|

|

panjang lmm |

||

|

julat |

tol. |

|

|

330 |

+5,-0 |

|

|

taip: c b t 3 0 5 mesin ujian lentur elektronik yang dikawal mikrokomputer ketepatan: 1n gb/t3851-1983 ≈iso3327-1982 astm b406-1996 |

|

taip: r b 2 0 0 0 r penguji kekerasan rockwell amerika syarikat wilson gb/t3849-1983 ukano3788/1-1982 astm b294-1992 |

|

taip: ld j - 5800 meter prestasi magnet ujian ketepuan magnet dan paksaan yang diimport semua mesin dalam satu |

|

baki elektronik: xs105 saya ttler toledo ketepatan: 0.01mg gb/t3850 ≈iso3369 astm b294 |

|

mikroskop metallographic: imej r .a2m carlzeiss gbt3479-1983 ≈iso4505-1978 astm b276-2005 gbt3448-1983 ≈iso4499-1978 astm b390-1992 |

instrumen ujian harta

pertanyaan

kategori produk yang berkaitan

- china 1 4 end mill

- kilang akhir bawah flat china

- pengilang alat pemotongan china

- china cnc router end mills

- china cnc bits end mill milling cutter

- alat pemotongan china

- kekosan bar aloi yang disusun

- cincin gulungan tungsten yang dipolis

- tongkat karbida simen

- alat pemotongan pemesinan

- sisipan karbida tungsten simen

- sisipan karbida simen cnc

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de